Open by image click

As the picture above shows, Fastfoot® prevents the footing concrete from being contaminated by mud and water, leading to a stronger concrete.

In the summer, Fastfoot® prevents rapid evaporation of moisture in the sides and bottom of the footing. This ensures adequate moisture for proper hydration of the cement particles.

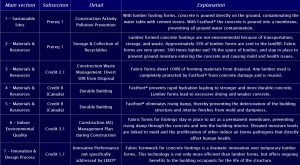

Installation Guide

The Fastfoot® footing membrane is a cost effective and green method of forming concrete footings. This installation covers strip footings where a single width of Fastfoot® is used to form both sides of the footing.

For wider footings or for deep pads where Fastfoot® only forms one edge of the footing or pad

Open by image click

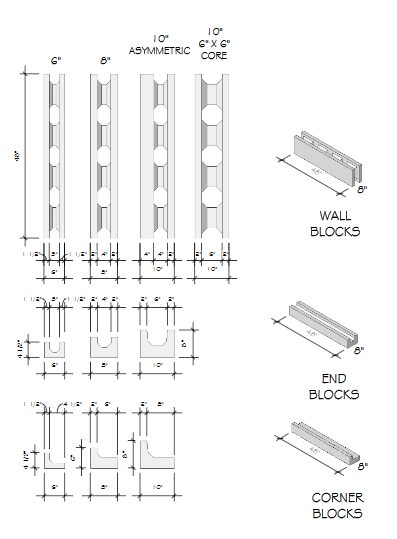

Fastfoot® comes in three widths:

- FF50 – Narrow, 50″ wide, suitable for footings up to 18″ wide and 10″ deep

- FF62 – Standard, 62″ wide, suitable for footings up to 24″ wide and 13″ deep

- FF74 – Wide, 74″ wide, suitable for footings up to 36″ wide and 13″ deep

Deeper footings can be accomodated wider fabric. Where necessary fabric can be run down each side and the two fabrics nailed into ground to prevent slipage. Note: if the fabric height is greater than 15″, install a second 2×4 to reduce the bulge and fabric tension.

FABRIC WIDTH SIZING RULE – Width required = footing width + 2 x footing height + 10″.

Layout the outside footing stakes (steel or 1x4s) around the perimeter of the foundation using a string line. Drive the stakes on this line about 6′ on center. Reduce spacing for deeper footings or when the ground is less dense.

Drive the inside stakes opposite each outside stake using a 1×2 cut to the footing width.

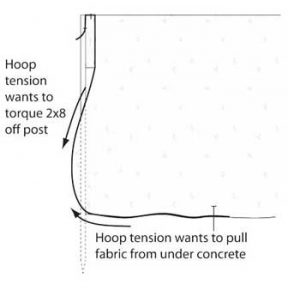

SOLIDLY attach screed boards to stakes. Fabric tension wants to torque the screed board off the stake. Use two angled nails or one screw per stake of suffient length to penetrate the full depth.

Fastfoot® easily adjusts to different footing depths. Determine the correct location of the fabric edge on the screedboard by:

- Place one hand on correct ‘footing width line’ on ground and bring fabric edge snugly over the screed board.

- Note the location of a colored ‘edge line’ with respect to the screed board under the fabric. Use this ‘edge line’ to position the fabric for stapling AS LONG AS the footing depth stays the same.

- If the footing depth increases, let the fabric OUT by place hand on the same ‘width line’ and note the new edge line over the screed board.

Using the edge line as determined in step 2, staple both corner edges to the screed boards at 12″ on centre, using a hammer tacker with 3/8″ staples.

If sewn corners are not available, click here for folding Fastfoot® on corners.

Hammer tack two edges of the Fastfoot® roll on top of the corner fabric with a 10″ overlap. Unroll past next corner and cut with a 10″ overlap. Hammer tack both edges 12″ on center using the predetermined edge line.

Nail center line to prevent movement by wind and concrete. Use sheathing tape on overlaps and nail holes to prevent concrete escaping form and moisture entering footing.

Run fabric through junction. Cut an inverted ‘T’ in junction area with lower cut along footing width line equal to the width of the footing width lines. Fold and staple tabs.

Run intersecting fabric into junction allowing a 10″ overlap. Cut overlap along footing width line, and staple overlaping tabs to screed boards.

Drive pairs of 2×4 stakes into the ground and nail (or screw) to upper and lower screed boards. Drive additional stakes if the distance between the stake and bank is greater than 15″. Install lower level Fastfoot®.

Run Fastfoot® up bank to form step. If step is too deep to form with a single width of fabric, either run two widths of fabric (edging) or turn the fabric 90 degrees to obtain the required width.

Install the upper level Fastfoot® with a 10″ overlap past top of step. Cut the overlap on the footing width lines, letting the center portion hang down bank.

Screw plywood bulkhead in position and brace. Note that the fabric can also be installed without cutting. Place a fold on the top edge equal to the height of the footing at that point.

Concrete is ‘hygroscopic’, meaning ground moisture wicks up through the footing concrete and inside the building. Fastfoot® is a vapor barrier which prevents this wicking.

After pouring the footing concrete, leave screed boards in place to hold Fastfoot® in position. Pull Fastfoot® off screed boards and lay under wall forms. Use 2″ sheathing tape to hold in position. Form and pour the foundation wall. Then run a 12″ width of ‘Peel & Stick’ along top of footing (covering any staple holes in Fastfoot®) and up the side of the wall. Lap bottom edge of wall membrane over vertical ‘Peel & Stick’.

On the inside of the footing, tape the underslab membrane to Fastfoot®.

Open by image click

Rising damp is the wicking of water through the footing, into the concrete wall, and its evaporation inside the building. Rising damp increases the moisture load which leads to dampness and mold.

Rising damp does not produce pools of water (as with liquid water entering a concrete wall), but rather a chronic musty smell, growing insidiously stronger when the footing is exposed to more moisture.

The worst case of rising damp occurs when water ponding occurs at the footing level. This occurs over impervious soils where the excavation is inadequately sloped, the drain tiles are not located below the bottom of the footing, and no sub-footing drainage layer was installed.

Even without water ponding, rising damp occurs when unprotected footings are exposed to damp ground. ‘Hygroscopic’ concrete wicks ground moisture up into the foundation concrete which is then evaporated inside the building. Fastfoot® prevents this wicking from occurring, providing a drier and healthier indoor environment.

Rising damp is prevented by isolating the concrete footing from ground moisture. While it is normal in the industry to protect the foundation wall from ground moisture with a damp proof membrane, no effort is made to protect the footing concrete. However most moisture is located at the bottom of the excavation, where the footings are located.

With impervious subsoils it is important to prevent water ponding from occurring at the bottom of the excavation. Four preventative steps should be taken: first, place a slight grade on the excavation so that ponding cannot occur; second, place a non-wicking drainage layer under the footing to enable any ground water to exit to the perimeter drain system; third, locate the bottom of the drainpipe below the bottom of the footing concrete; and fourth, use Fastfoot® to protect the concrete footing from ground moisture on the bottom, sides and top of the footing.

Both water ponding and rising damp is evident in this crawlspace in Surrey BC. Note the effervescence on the stem walls from rising damp travelling up through the footing, into the stem wall and evaporating inside the crawl space.

Poor drainage, an improperly sloped excavation, and no sub-footing drainage layer caused water ponding. No damp proof membrane around the footing resulted in rising damp.

Humidity levels are 100%, resulting in mold and mildew and a very unhealthy envirnoment for the homeowner.

In the image to the right, water ponding is occurring because of inadequate slope in the excavation, no drainage layer under the footing, and the drain tile located above the bottom of the footing.

The photo to the right shows an excavation where there is inadequate slope on the excavation, no drainage layer, and the drain pipes are positioned above the bottom of the footing. As there is no damp proof protection around the footing, there is a high probability of rising damp occurring for the life of the buildings.

Open by image click

A single 12.5 pound roll of Fastfoot® forms the same footing as 900 pounds of lumber, representing a dramatic increase in efficiency. Footing lumber is discarded after several reuses because of alkaline damage. Fastfoot® protects all lumber and stakes from concrete.

The photo on the right shows the typical footing lumber on a residential foundation in Vancouver BC. The photo insert shows Fastfoot® with sewn corners, where not a single piece of lumber was used to form the concrete. The fabric stays in place to prevent ground moisture from entering the foundation concrete.

GreenSpec® is the highly respected green products directory produced by BuildingGreen, Inc. The company does not charge for listings or for the review process, nor do they accept advertising. As their resources are totally subscription supported, they have complete editorial independence and integrity – providing information that can be trusted.

“GreenSpec is the best resource in my collection of sustainable product guides and I refer to it frequently for my own projects and when providing recommendations for others.”

Grant Crosby, Historical Architect, National Park Service (Alaska Region).

The Fastfoot® membrane prevents moisture from wicking up through the concrete footing into the home. This prevents mold and fungi that grow in damp environments and can cause severe respiratory infections and allergic reactions.

Concrete is ‘hygroscopic’, meaning ground moisture wicks up through the footing concrete and inside the building. Fastfoot® is a vapor barrier which prevents this wicking.

FASTFOOT® COMMERCIAL

Open by image click

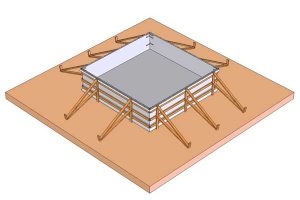

Above left: Fastfoot®: a single 2×8 screed board hinged at each corner for rapid deployment and stripping, with Fastfoot® quickly stapled in position. The weight of Fastfoot® for these 10′ x 10′ x 24″ pads (including screed board and bracing) is 4.6 pounds a running foot.

Plywood weighs over 14 pounds a running foot, over three times Fastfoot®. Note how the contractor has shoveled sand around the base to prevent blowouts. This is never required with Fastfoot®.

In the left photo, the contractor uses minimal bracing: three single kickers on each side, with no lateral support on bottom. Lateral pressures are reduced 50% with Fastfoot®, with no lateral pressure at the bottom. This makes installation and stripping fast and lowers costs significantly.

With plywood, concrete pressure is highest at the bottom, requiring significant support at base to prevent blowouts. In this photo the contractor supports the bottom of his form with stakes and sand to prevent blowouts.

With Fastfoot® the 2×8 is adjusted to the exact elevation of the top of the pad, with fabric filling between the screed board and ground. Screeding is fast, easy and efficient.

With plywood, the top of the form is seldom the top of the pad, requiring the installation of a 1×2 leveling strip around the inside. Concrete placement and finishing is difficult and time consuming. (Note the form blowout, requiring rapid deployment of broken concrete from a previous plywood form failure.)

As Fastfoot® is ‘sacrificed’, there are no inventory limitations of the size of the pour. The left photo (with bracing removed) shows the first pour; the right photo is the second pour. The number of pads poured each day was a function of the speed of the concrete pump and the supply of concrete, not form inventory.

With plywood, the size of the pour is constrained by the plywood in stock. If this project was formed with plywood, 18,000 pounds of form materials would have been required for each of the two pours, and a crane to move the panels across the site.

Rising Damp Prevention & Ground Water Contamination

Concrete is hydroscopic, wicking up ground water which then enters the interior of the structure. This is why underground garages have very high humidity levels. Note the damp color of the sand, indicating moisture wicking up from the water table below.

Fastfoot® is a damp proof membrane which prevents ground moisture wicking up into the concrete, thereby providing a dry and healthy indoor air environment. The membrane also prevents cement fines leaching into the ground water table.

Plywood is an open form providing NO protection against ground moisture, leading to damp concrete for the life of the building. Cement fines contaminate the water table.

Fastfoot® is an inexpensive form that uses minimal resources. Evern: the small amount of lumber is protected by fabric and lasts indefinitely. No recycling costs with Fastfoot®.

Plywood forms are heavy and expensive. They have a short life as a temporary form, then must be stripped, cleaned, treated, transported, stored, and ultimately discarded in a land fill. This requires great amounts of labor and energy.

Open by image click

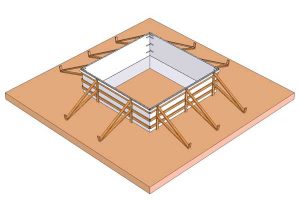

Fastfoot® Edging is a cost effective, green forming method for large footings and pads.

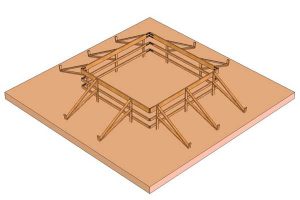

The support structure (‘fence’) for the fabric consists of 2×4 posts (stakes) spaced approximately 4 to 6′ on center with horizontal members (‘rails’) attached to the inside of these posts.

The top rail (‘screed board’, usually a 2×8), is attached at the height of the top of the footing. If the distance between the ground and the bottom of the screed board is greater than 16″, an additional rail (sized 2×4 or 2×6) is added to reduce the bulge and fabric tension. Footings 3′ and over should have two rails in addition to the screed board.

When concrete is placed inside the fabric-covered fence, ‘hoop’ tension is induced in the fabric which pulls down on the screed board and pulls the bottom edge from under the concrete. The screed board must be solidly attached to each post and sufficient fabric placed under the concrete to prevent slippage.

Lateral forces in rigid forms are up to 50% higher than with Fastfoot®, often leading to failure.

With Fastfoot® the pressures at the bottom of the form are taken by the friction of the fabric under the concrete.

Cut 2x8s to length to achieve dimensions of footing or pad. Nail or screw corners together and reinforce with metal strapping to withstand concrete forces.

If using the same formwork multiple times, use strap hinges with a removable pin. Locate screed board in exact position.

Drive Posts into Ground

Drive sharpened 2x4s into the ground around the perimeter of the screed board 6′ on center. For pads deeper than 2′-6″ reduce spacing to 4′.

If the ground is too hard for 2x4s, drive metal stakes 1-1/2″ outside the screed board using an electric hammer. Screw attach 2×4 uprights to each metal stake.

Use a laser or builders level to mark footing height on the stakes or uprights. Lift up the screed board perimeter to the footing height and solidly attach with nails or screws.

SOLIDLY attach screed board to each post. Fabric tension wants to torque screed board off post. Use at least four angled nails or two screws per post long enough to penetrate full depth.

If the distance between the ground and bottom of screed board is greater than 16″ attach an additional 2×4 or 2×6 rail. This reduces fabric tension and bulging. If two rails are required, reduce the spacing on the lower horizontal member where pressure is higher. Metal-strap or strap-hinge all corners.

Brace Fence Posts

Lateral bracing is critical. Drive stakes into the ground 6-7′ outside each post. Run two kickers: one off the top and one off the middle of each post to the ground stake. There is no need to brace bottom of post as these loads are taken by fabric tension.

Form uplift will not occur as fabric tension pulls formwork down.

To determine Fastfoot width, add: height of the footing + distance between ground and first horizontal member + 20″. Fastfoot is available in three widths: 50″, 62″ and 74″. FF74 rolls can be cut in half with a chop saw to provide a 37″ width.

Use a hammer tacker with 3/8″ staples. Tension on staples increases as the distance between the screed board and ground (or next rail) increases. Staple at least 2″ away from fabric edge as staples can pull through edge. For ease, staple fabric on top of screed board about 2″on center and drive staples flush with fabric. Stapling is all about speed and cadence.

Nail fabric edge to ground 5′ on center to lock in place.

To prevent excessive fabric bulging, bring the fabric straight down from the forms and nail fabric edge to prevent movement 3′ on center. Fold the corners neatly and nail in place.

Steel installation is done as normal.

Place Concrete

Place concrete along fabric edge on ground to prevent concrete lifting edge. Fill the form evenly around the perimeter and in lifts no more than 12″ high. Allow concrete to stiffen before next lift to reduce fabric tension and load on kickers.

A single 12.5 pound roll of Fastfoot® forms the same footing as 900 pounds of lumber, representing a dramatic increase in efficiency. Footing lumber is discarded after several reuses because of alkaline damage. Fastfoot® protects all lumber and stakes from concrete.

The photo on the right shows the typical footing lumber on a residential foundation in Vancouver BC. The photo insert shows Fastfoot® with sewn corners, where not a single piece of lumber was used to form the concrete. The fabric stays in place to prevent ground moisture from entering the foundation concrete.

GreenSpec® is the highly respected green products directory produced by BuildingGreen, Inc. The company does not charge for listings or for the review process, nor do they accept advertising. As their resources are totally subscription supported, they have complete editorial independence and integrity – providing information that can be trusted.

“GreenSpec is the best resource in my collection of sustainable product guides and I refer to it frequently for my own projects and when providing recommendations for others.”

Grant Crosby, Historical Architect, National Park Service (Alaska Region).

The Fastfoot® membrane prevents moisture from wicking up through the concrete footing into the home. This prevents mold and fungi that grow in damp environments and can cause severe respiratory infections and allergic reactions.

Concrete is ‘hygroscopic’, meaning ground moisture wicks up through the footing concrete and inside the building. Fastfoot® is a vapor barrier which prevents this wicking.

Fast Tube Overview

Open by image click

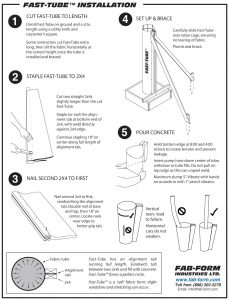

Fast-Tube™

Fast-Tube™ is a ‘soft’ fabric column form for forming round concrete columns. Manufactured from high strength polyethylene, Fast-Tube™ comes on rolls 100′ in length for diameters from 8″ to 12″ (in 2″ multiples) and 50′ lengths for diameters 14″ to 20″. Installation, pouring and stripping is quick and easy.

Sustainable Advantages

- Economic, see spreadsheet below

- No waste: cut any length from 100′ roll

- Ships flat, 1% the space of cardboard tubes

- Light weight, 10% the weight of cardboard tubes

- Strips in seconds

- Recycle as under slab membrane

A single roll of Fast-Tube™ 10″ diameter forms fifteen 8′ columns, yet weighs only 17.1 pounds and takes up the space of a brief case. The equivalent in cardboard tubes weights about 150 pounds and takes up almost 90 cubic feet. This efficiency in space and weight results in energy efficiency throughout manufacturing and distribution.

As cardboard columns are manufactured in short lengths, on the jobsite there is typicaly a 25% waste (see photo on the right) as the contractor cuts the tube to the required height. When the cardboard is stripped, all this material is sent to the landfill.

Stripped Fast-Tube™ is recycled as an underslab membrane.

GreenSpec® is the highly respected green products directory produced by BuildingGreen, Inc. The company does not charge for listings or for the review process, nor do they accept advertising. As their resources are totally subscription supported, they have complete editorial independence and integrity – providing information that can be trusted.

“GreenSpec is the best resource in my collection of sustainable product guides and I refer to it frequently for my own projects and when providing recommendations for others.”

Grant Crosby, Historical Architect, National Park Service (Alaska Region).

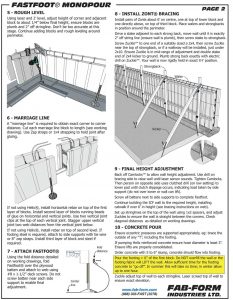

FAB FORM MONOPOUR

Open by image click

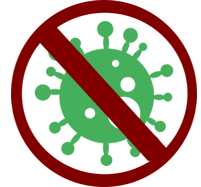

The system consists of four components:

- Drill adjustable side supports used to hold the ICF block the footing height above the ground;

- Fastfoot fabric used to contain and form the concrete footing under the ICF block;

- The ICF block itself;

- Zont bracing used to align and hold the foundation in position.

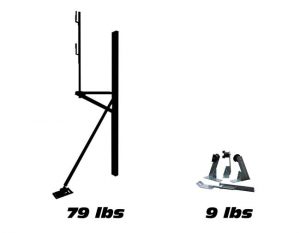

The bracing was designed specifically for use with the monopour system. Scaffolding loads are transferred directly to the ground through the strongback, without interfering with the footing concrete. The bracing is simple and cost effective, consisting of Zont™ brackets, Zuckle™ wall aligners, ZAT catwalk brackets and site available 2x4s. Click on the image above for more information.

A single roll of Fast-Tube™ 10″ diameter forms fifteen 8′ columns, yet weighs only 17.1 pounds and takes up the space of a brief case. The equivalent in cardboard tubes weights about 150 pounds and takes up almost 90 cubic feet. This efficiency in space and weight results in energy efficiency throughout manufacturing and distribution.

As cardboard columns are manufactured in short lengths, on the jobsite there is typicaly a 25% waste (see photo on the right) as the contractor cuts the tube to the required height. When the cardboard is stripped, all this material is sent to the landfill.

Stripped Fast-Tube™ is recycled as an underslab membrane.

GreenSpec® is the highly respected green products directory produced by BuildingGreen, Inc. The company does not charge for listings or for the review process, nor do they accept advertising. As their resources are totally subscription supported, they have complete editorial independence and integrity – providing information that can be trusted.

“GreenSpec is the best resource in my collection of sustainable product guides and I refer to it frequently for my own projects and when providing recommendations for others.”

Grant Crosby, Historical Architect, National Park Service (Alaska Region).

ZONT™ BRACING

Open by image click

Forming T-junctions with ZEEs eliminates three marriage lines at each junction. As each marriage line takes approximately 40 minutes to cut, reinforce with 1x4s and strip, that’s a lot of wasted labour. In the photo below, no marriage lines were required using ZEEs.

As each marriage line requires cutting the ICF block on each side of the line, this leads to excessive ICF waste.

A single roll of Fast-Tube™ 10″ diameter forms fifteen 8′ columns, yet weighs only 17.1 pounds and takes up the space of a brief case. The equivalent in cardboard tubes weights about 150 pounds and takes up almost 90 cubic feet. This efficiency in space and weight results in energy efficiency throughout manufacturing and distribution.

As cardboard columns are manufactured in short lengths, on the jobsite there is typicaly a 25% waste (see photo on the right) as the contractor cuts the tube to the required height. When the cardboard is stripped, all this material is sent to the landfill.

Stripped Fast-Tube™ is recycled as an underslab membrane.

GreenSpec® is the highly respected green products directory produced by BuildingGreen, Inc. The company does not charge for listings or for the review process, nor do they accept advertising. As their resources are totally subscription supported, they have complete editorial independence and integrity – providing information that can be trusted.

“GreenSpec is the best resource in my collection of sustainable product guides and I refer to it frequently for my own projects and when providing recommendations for others.”

Grant Crosby, Historical Architect, National Park Service (Alaska Region).